Do you have a Livestock Feedlot? Have you ever considered a

Solar Power Feed Bunk Cover Shade for your feedlot? With a clean energy solar system such this

CAD Solar System design by Scotty you will be not only providing

cover and shade for your livestock when they are feeding, it will generate income from the Sun for your operation.

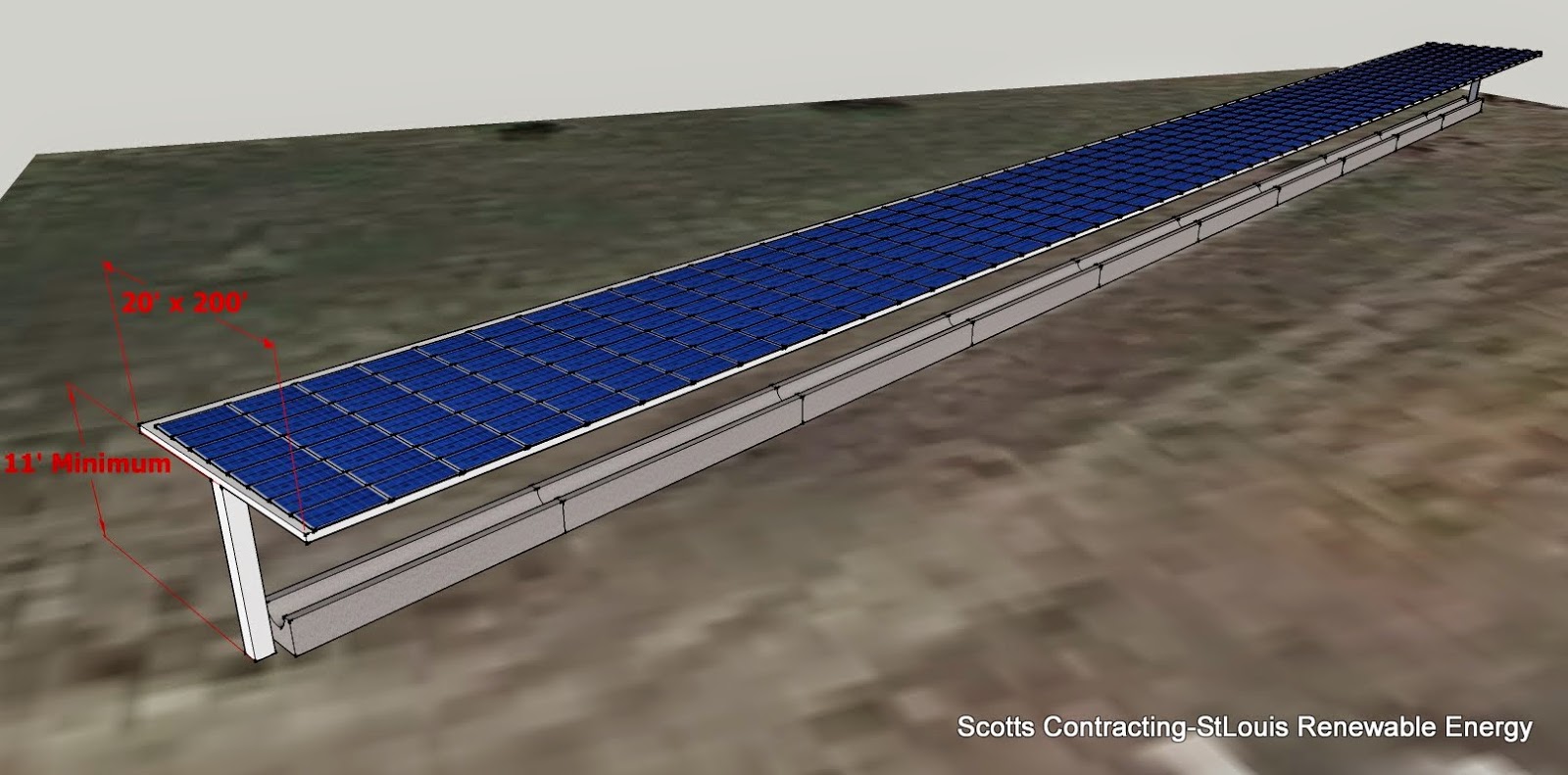

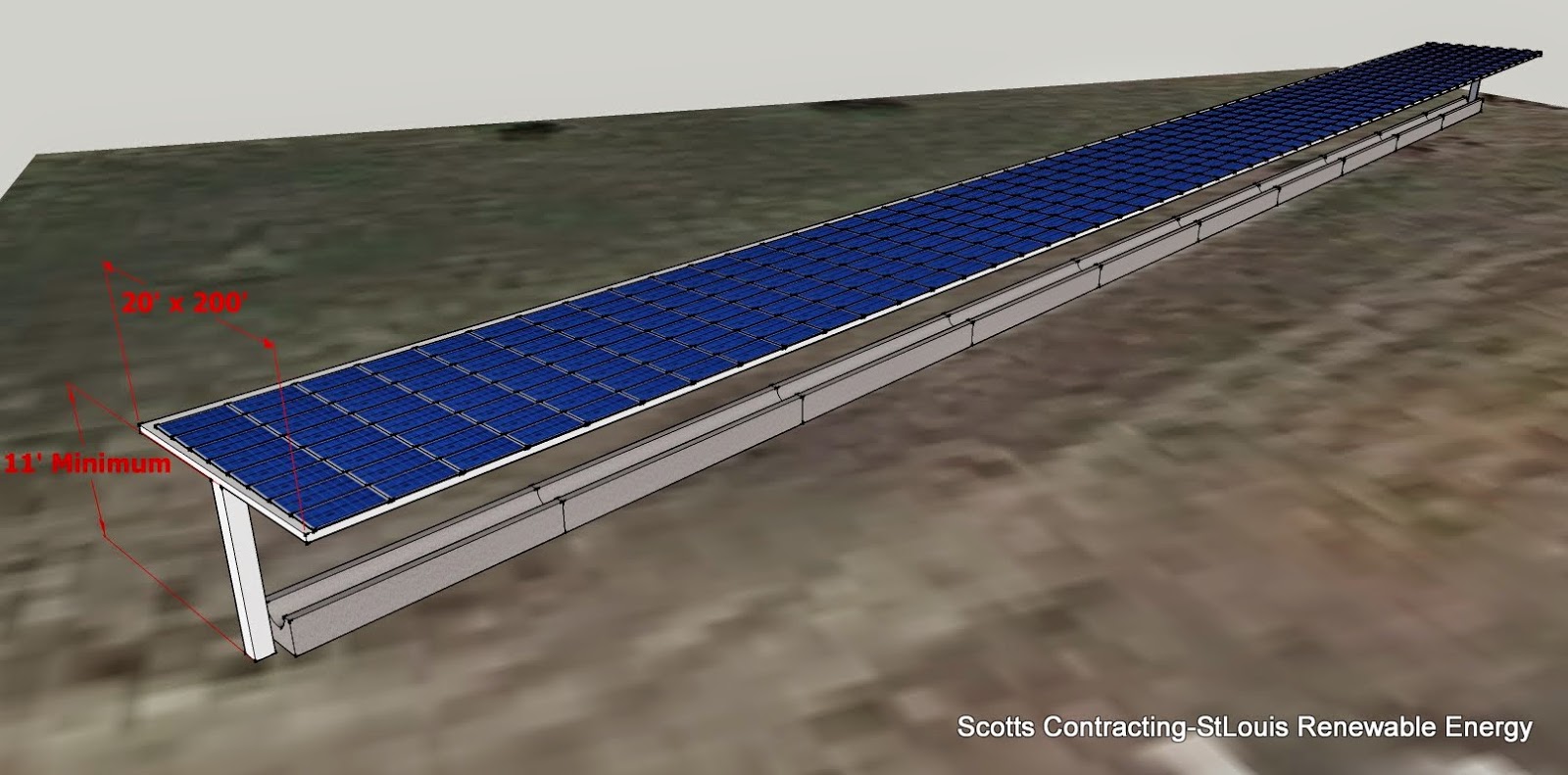

The Solar Feed Bunk Cover Shade in these pictures is designed with

American SunPower Solar Panels, covers 4000 sq feet, and is estimated to produce 59,680 watts of clean pollution free energy (based on 230w panels that produce 14.92 w/sq ft-

(Other higher Output power producing solar panels are available-I used the 230w solar panels since they were already integrated into my computer drafting program from past Solar Projects I've designed. To get the most bang for the buck I recommend the 300 or 400 watt solar panels )

The following

CAD designs are examples of the

Solar Power Feedbunk Cover - Shade designed by Scotts Contracting-StLouis Renewable Energy that could be added to your

existing structure or could be

site built to fit your cattle feeding operation. This example uses my Fathers Missouri Beef Cattle Operation.

The

Solar Power Feed Bunk Cover Shade can be added to an existing

beef cattle feedlot such as the one pictured below.

If an existing Feedlot shading system is not already in place it is possible to design build a Solar Power Shade to fit over your existing feed bunks.

|

| it is possible to design build a Solar Power Shade to fit over your existing feed bunks |

Birds Eye view of the SolarPower Feed Bunk Cover Shade, Cattle Pens, Barns, and Silo

|

| Birds Eye view of the SolarPower Feed Bunk Cover Shade, Cattle Pens, Barns, and Silo |

The following Diagram is the Suns yearly path over the SolarPower Feed Bunk Cover Shade

Rural Energy for America Program -

Rural Energy for America Program (REAP)- Renewable Energy System and Energy Efficiency Improvement Guaranteed Loan and Grant Program – Financing The maximum amount of a REAP Guaranteed Loan is $25 million per loan request. The minimum loan amount is $5,000. Up to 75 percent of total eligible project costs can be covered through the REAP Guaranteed Loan Program.

The Program provides guarantees to commercial lenders who make loans to rural small businesses or agricultural producers for energy projects. The rates and terms of these loans are negotiated between the lenders and the borrowers.

The following guarantee limits apply:

85 percent for loans of $600,000 or less

80 percent for loans greater than $600,000 up to $5 million

70 percent for loans greater than $5 million up to $10 million

60 percent for loans greater than $10 million up to $25 million

The following grant amounts apply:

The minimum Renewable Energy System Grant request is $2,500 up to a maximum of 25 percent of eligible project costs or $500,000, whichever is less.

The minimum Energy Efficiency Improvement Grant request is $1,500 up to a maximum of 25 percent of eligible project costs or $250,000, whichever is less.

The following amounts apply to combination guaranteed loan and grant limits apply:

The combined request cannot exceed 75 percent of total eligible project cost

The above guarantee limits apply

The maximum REAP Guaranteed Loan is $25 million per loan request

The maximum Renewable Energy System Grant request is 25 percent of eligible project costs or $500,000, whichever is less

The maximum Energy Efficiency Improvement Grant request is 25 percent of eligible project costs or $250,000, whichever is less $250,000

The minimum combined funding request allowed is $5,000, with the grant portion of the funding request being at least $1,500 see http://www.rurdev.usda.gov/BCP_ReapResEei_Financing.html

Renewable Energy System and Energy Efficiency Improvement Guaranteed Loan and Grant Program – Eligibility

Guaranteed Loan and grant eligibility is limited to rural small businesses and agricultural producers. An agricultural producer is an individual or entity directly engaged in the production of agricultural products (crops, livestock, forestry products, hydroponics, nursery, and aquaculture) whereby 50 percent + or greater of their gross income is derived from the operations. A private entity is considered a small business in accordance with Small Business Administration’s Small Business Size Standards.

The lender must be eligible for the program. Most lenders are eligible, including Federal and State-chartered banks, Farm Credit System banks, and savings and loan associations. Other lenders may be eligible if approved by USDA.

For both loan guarantees and grants, project must meet the following conditions:

The loan/grant must go towards the purchase of a renewable energy system or to make energy efficiency improvements

The technology is pre-commercial or commercially available, and replicable

The project must have technical merit, as specified in Rural Development Regulation 4280 subpart B

A rural small business must be located in a rural area, though an agriculture producer may be located in a rural or non-rural area

The applicant must be the owner of the project and control the revenues, expenses, operations, and maintenance of the project

Sites must be controlled by the agricultural producer or small business for the financing term of any associated Federal loans or loan guarantees

The project must have satisfactory sources of revenue, for the life of the project, that will be used for the operation, management, maintenance, and debt service of the project

Eligible project costs for Renewable Energy Systems and Energy Efficiency Improvements are:

Post-application purchase and installation of equipment (new, refurbished, or remanufactured), except agricultural tillage equipment, used equipment, and vehicles

Post-application construction or improvements, except residential

Energy audits or assessments

Permit and license fees

Professional service fees, except for application preparation

Feasibility studies and Technical Reports

Business Plans and Retrofitting

Construction of a new energy efficient facility only when: the facility is used for the same purpose; is approximately the same size; and, based on the energy audit, will provide more energy savings than improving an existing facility. Only costs identified in the energy audit for energy efficiency improvements are allowed. New equipment as long as it is of similar size to the equipment being replaced

Working capital (applicable for guaranteed loan only)

Land acquisition (applicable for guaranteed loan only)

see http://www.rurdev.usda.gov/BCP_ReapResEei_Eligibility.html

|

Renewable Energy System and Energy Efficiency Improvement Guaranteed Loan and Grant Program – Technology

Renewable Energy System and Energy Efficiency Improvement Grants must be used towards the project cost for the purchase, installation and construction of renewable energy generation systems.

Eligible technologies under the program are divided into two categories:

1.) Renewable Energy Projects

Biomass, bio-energy: produces fuel (e.g., biodiesel, ethanol), thermal energy, or electric power from a biomass source (crops, trees, wood, plants, their residues and fats, oils, and greases, and other biodegradable waste material)

Biomass, anaerobic digesters: produces thermal energy or electric power via anaerobic digestion using animal waste & other organic substrates

Geothermal, electric generation: electric power from the thermal potential of a geothermal source

Geothermal, direct use: produces thermal energy directly from a geothermal source

Hydrogen: renewable energy systems using hydrogen as an energy transport medium

Solar, small: electric projects with rated power ≤ 10 kW; thermal projects with rated storage ≤ 240 gallons

Solar, large: electric projects with rated power >10 kW; thermal projects with rated storage >240 gallons

Wind, small: systems with a ≤ 100 kW-rated wind turbine & with a generator hub height of ≤ 120 feet

Wind, large: systems with a >100 kW-rated wind turbine

Hydroelectric: electric power from small hydro projects of 30 MW or less

Ocean: energy generation from tidal, wave, current, and thermal sources – but not for R&D technologies

Flexible Fuel Pump: a retail pump that combines and dispenses a blended liquid transportation fuel or dispenses a blended liquid transportation fuel

2.) Energy Efficiency Improvements Projects include any energy savings measures to businesses or agricultural operations including but not limited to replacement of inefficient equipment, retrofitting, insulation or any recommended improvement identified in the energy assessment or energy audit.

|

|

REAP Application Resources and Templates via Farm Energy .Org

http://farmenergy.org/tools/tools-and-templates

This and related pages are being updated to reflect changes in the new Rural Energy for America Program – REAP from the 2014 Farm Bill. The materials and links on this page will help applicants more efficiently prepare effective REAP applications.

Is it important that applicants contact their state USDA Energy Coordinator early in the application process. Your state Energy Coordinator needs to perform an environmental review at the project site that must be completed for your application. They can help to review your project for program eligibility, for application assistance and to learn about additional resources specific to your state and region. (Plus, the State offices directly allocate some REAP funds).

The Missouri Office and Contact Person is:

Matt Moore, USDA Rural Development

601 Business Loop 70 West

Parkade Center, Suite 235

Columbia, MO 65203

573.876.9321

matt.moore@mo.usda.gov

|

|

While I pride myself for being inventive, futuristic, and having the entrepreneurial spirit. I realized today while searching Google Beef Feedlot images that I wasn't the first one to realize the potential of bringing solar panels to the Feedlot and Beef Cattle Industry.

I tip my hat to Feed Central!

www.feedcentral.com.au/contact.asp

10775 Warrego Highway

Charlton QLD 4350, Australia

Thank You for stopping by-Share and Comment below. If additional information in needed or you have a question let me know. Together we can make a difference. Build a Green StLouis

Get Your Green Building Tips and Resources at St Louis Renewable Energy Green Blog